Paints should be used for a specific application and environment. Knowing what type of paint should be used, and knowing what type of paint was used previously, is valuable information in any manufacturing or construction job.

Materials Identification & Characterisation

Paints should be used for a specific application and environment. Knowing what type of paint should be used, and knowing what type of paint was used previously, is valuable information in any manufacturing or construction job.

In a coastal environment, painting or repainting a masonry surface or painting railings or street furniture requires that the paint is correct both for the surfaces onto which it is being applied and suitable for the service environment. Knowing this is one of surest ways to say with confidence, that the paint is right for the job.

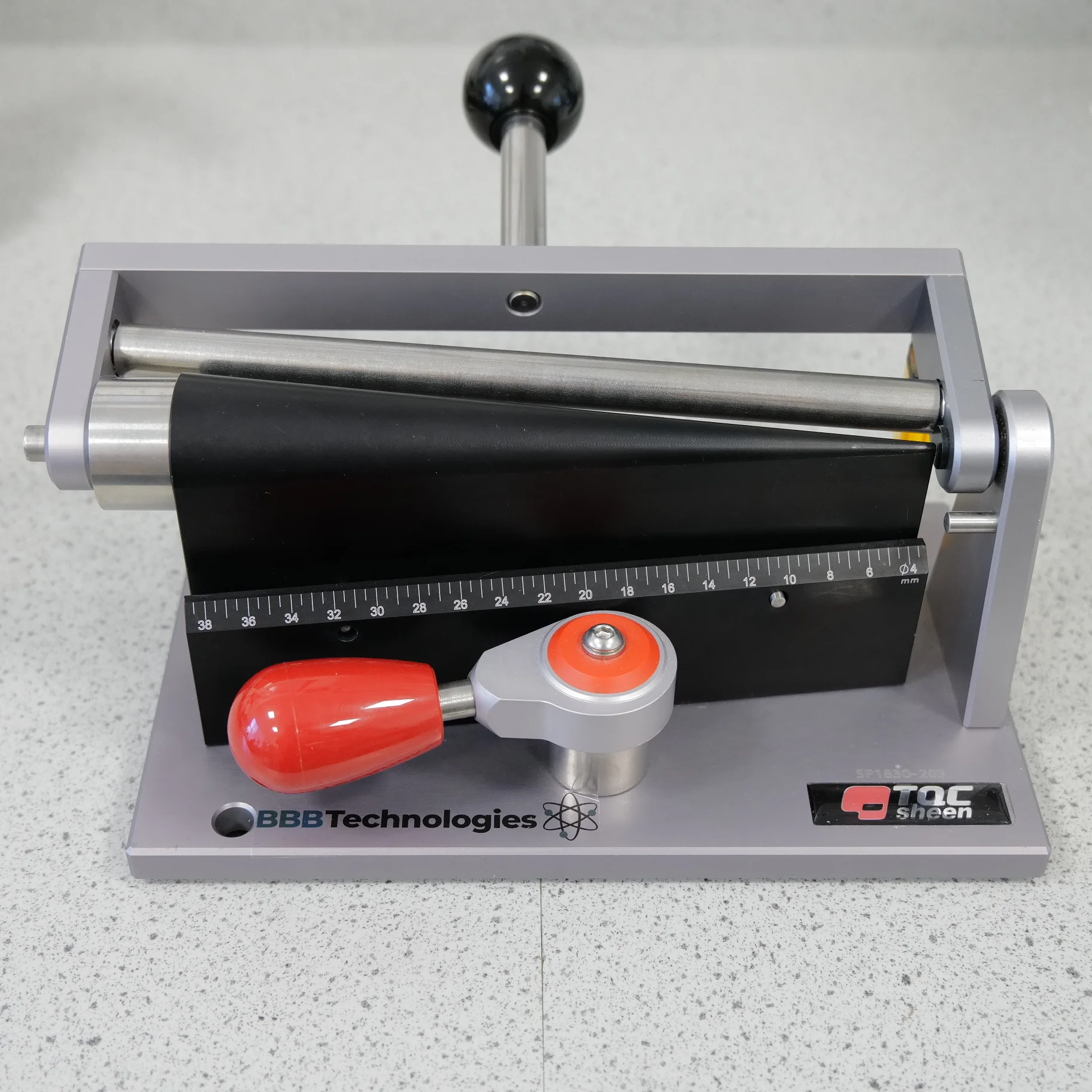

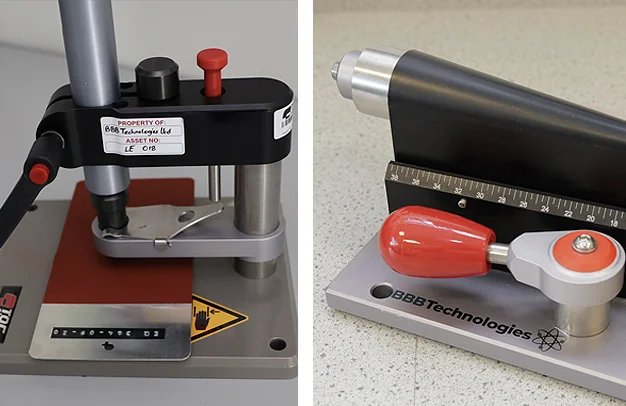

Our laboratory investigation and scientifically valid test protocols are the most in-depth available in Ireland and allow us to scientifically examine and test any liquid paint or dried paint film for both chemical and physical properties. Using Scanning Electron microscopy (SEM) with Energy Dispersive Spectroscopy (EDS), we can determine for example, what type of pigments were used to manufacture the paint. Using Fourier Transform Infrared Spectroscopy (FT-IR), we can determine the chemical composition of the polymeric resin and some additives.

Through extensive physical and or chemical testing of a liquid paint or dry paint film, the ability to know if the suggested paint or paint system is suitable for the intended application and understand what type of paint was used for any manufacturing, construction, or renovation application.

As an example, repainting exterior steelwork requires that there is no interaction between the existing paint and the proposed newly applied paint.

The Problem: A state agency contacted us requesting assistance in identifying the chemical composition of an interior decorative paint which was found on the window frames of a building listed on the National Inventory of Architectural Heritage. It was thought that the paint film may contain lead and if this was found to be fact, special removal techniques would be required.

The Process: Our laboratory was contacted, and we dispatched a chemist to the site where using a scalpel, he could remove small specimens of the paint film from different areas and place them in individually numbered bags.

The Result: Using Scanning Electron Microscopy (SEM) with Energy Dispersive Spectroscopy (EDS) all the paint specimens were examined for their elemental composition, and it was found that the white pigment used in the paint was a combination of titanium dioxide and zinc oxide, with lead being detected as background level readings. Our client was exceptionally happy with our services and the result obtained.

Paint manufacturers, Specifiers, Sales Agents, Production Managers, Architects, Building Contractors, Surveyors and Solicitors.

Our business is solving problems, so talk to us now.

Contact us