Do you manufacture, distribute, specify, or apply paint? Are you occasionally faced with a paint issue which seems insurmountable?

Failure Investigation

Do you manufacture, distribute, specify, or apply paint? Are you occasionally faced with a paint issue which seems insurmountable?

If so, we can provide an all-encompassing technical service to help you through the ins and outs of all aspects of paint science and technology.

Specifically in the determination of the root cause of paint failure, our decades of expertise and our suite of bespoke analytical equipment allow us to come to a court-qualified technical opinion as to how and why a paint failed in service.

In painting anything under the sun, there are four basis rules:

Now, what happens after six months or a year when it is found that the paint is flaking or peeling? What happens when this failing paint allows water to enter a building or allows the process of corrosion to commence.

The investigation of the in-service failure of paints and the technical examination of the material surfaces which was painted.

The investigation of the in-service failure of paints and the technical examination of the material surfaces which was painted.

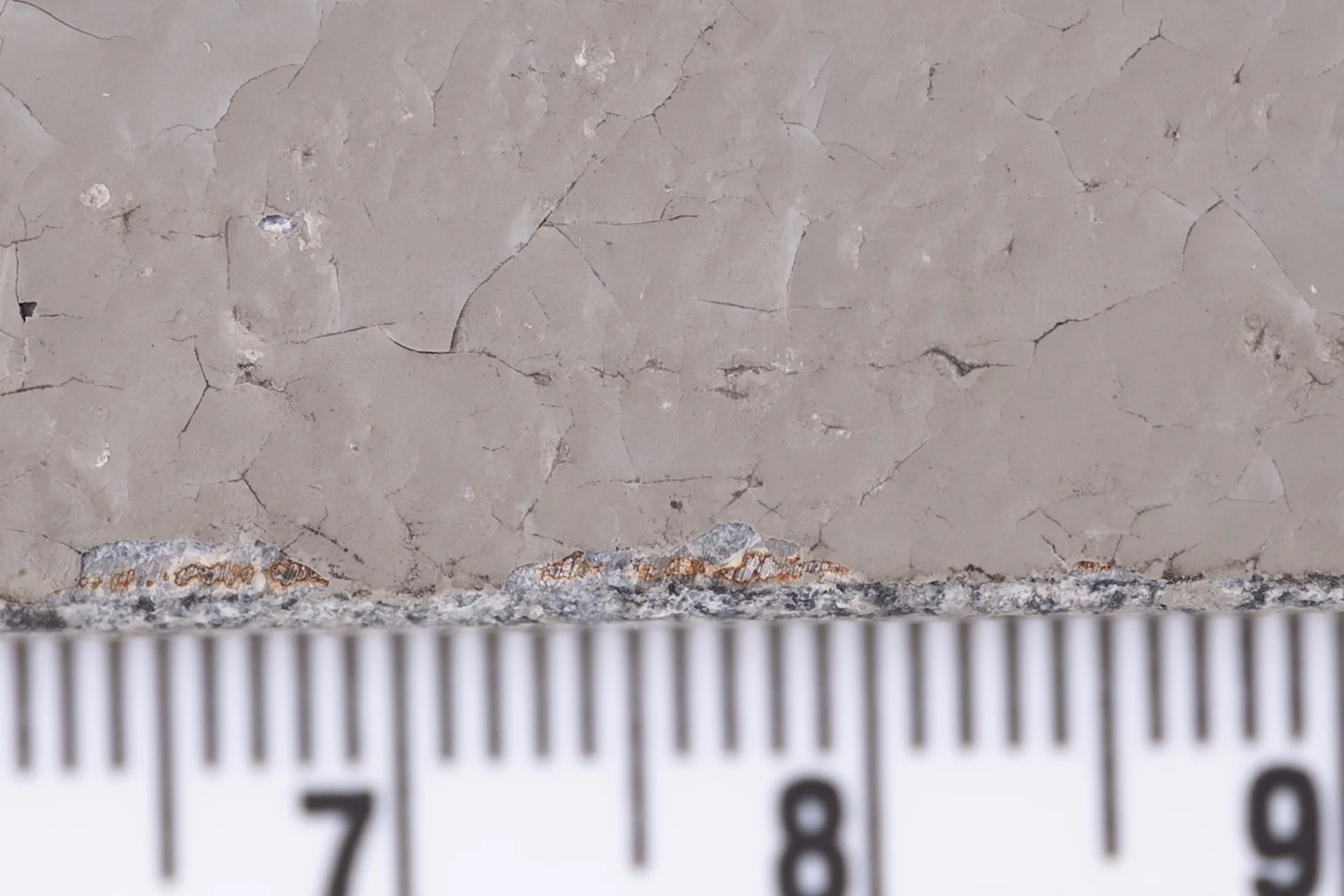

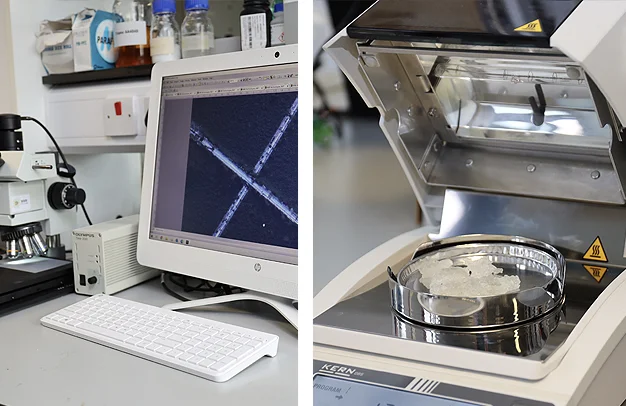

Our laboratory investigation and scientifically valid test protocols are the most in-depth available in Ireland. Using our precision sample cutting and mounting facility, we can embed any paint film in resin and using our ultra-modern scanning electron microscope and infrared spectrophotometer, we can examine and analyse each paint layer individually, not only measuring the film thickness of each paint layer but establishing the chemical composition of the paint in each layer.

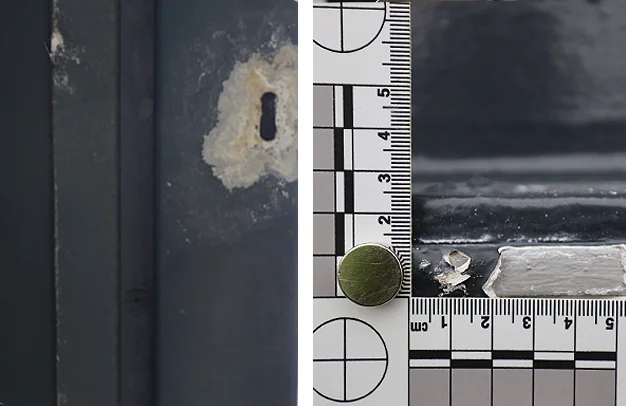

Our forensic microscopy equipment allows us to examine paint flakes and determine if the surface being painted, was correctly cleaned, and primed before paint application.

Our infrared microscope analysis of individual layers in a paint sample can be performed using an ATR technique, with the measurement positions and the dimension of the measured area can be defined individually for each paint layer.

So having these analytical resources at your fingertips allows us to establish the root cause of the paint failure and clearly establish where liability lies.

The Problem: A Quantity Surveyor contacted us and advised that paint failure was taking place on recently applied car park markings. With the aim of establishing the cause of the failure, a site visit was requested.

The Process: A materials engineer and chemist visited the site, marked, and photographed the areas where coating failure was visible and then went on to examine the areas more closely and remove samples of peeling paint for analysis.

The Result: Using Scanning Electron Microscopy (SEM) with Energy Dispersive Spectroscopy (EDS) the paint specimens were examined for their elemental composition. Our analysis showed the presence particulate dirt and debris adhering to and embedded in, the back of the dried paint flake…therefore the surface of the car park was not prepared in advance of painting. We also advised that the surface of the car park should have been primed before the application of the paint. The paint manufacturers paint application data advised that the surface to be painted must be clean and suitably primed. At the painting contractors’ expense, the car park was repainted.

In this case, our detailed forensic examination of the site, our interviews with the parties involved, our inspection of the data supplied and our in-depth analysis of the paint and the provision of a clearly written Technical Report, identified what had gone wrong and who was responsible for that wrong. There are many causes of paint failure, and the failure will be surrounded by hearsay and positions assumed when litigation is a strong possibility.

Take the unknown out of issues with paint. Our decades of expertise on paint chemistry and modes of failure, evidenced using our suite of analytical equipment, will provide a proof positive understanding as to why the paint is failing.

Paint manufacturers, Specifiers, Sales Agents, Production Managers, Architects, Building Contractors, Surveyors and Solicitors.

Olympus BXFM

Our business is solving problems, so talk to us now.

Contact us