How we found a solution for our client

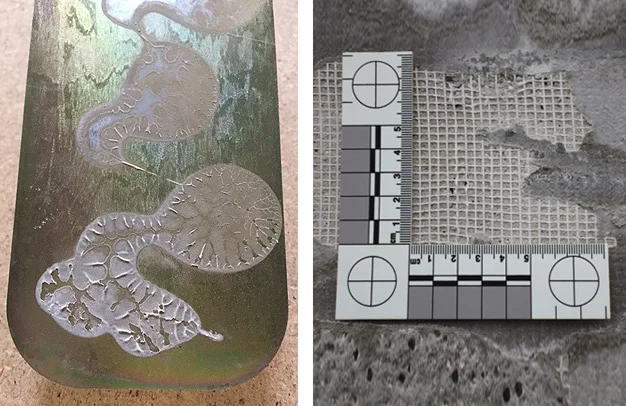

The Problem: A manufacturer of vehicle advertising decals was buying a two-component polyurethane adhesive which was used to bond the advertisement to the van body. It was soon evident that several business owners were unhappy with freshly applied advertising as after three weeks exposure to wind and rain, the decals were losing their colour and delaminating.

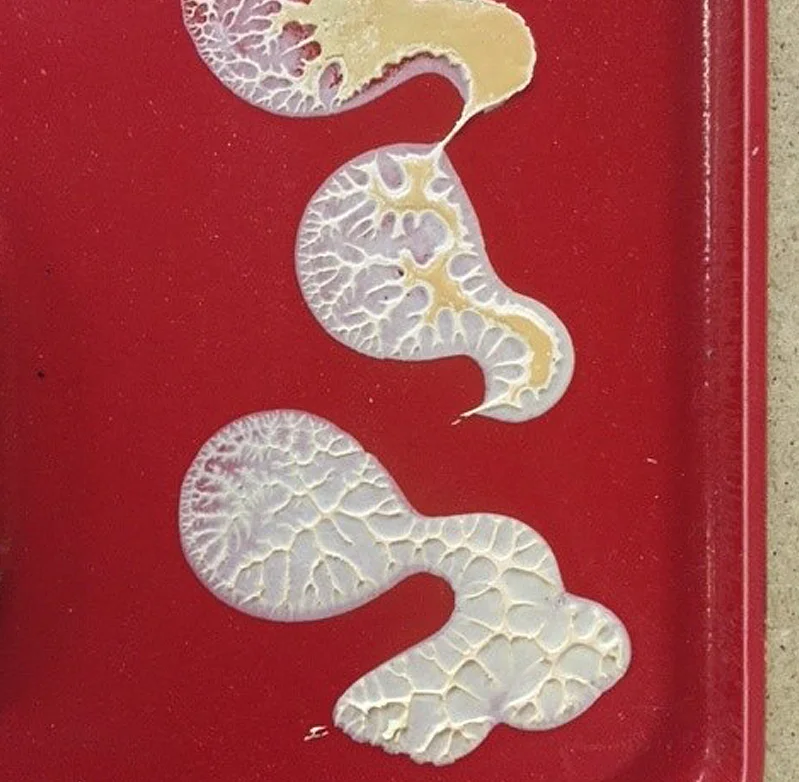

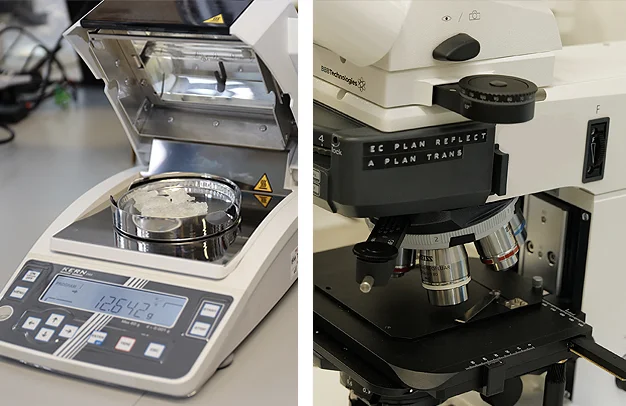

The Process: Our laboratory was contacted, and we dispatched a materials engineer to commence the investigation. This process involved inspecting the decals adhering to the van, inspecting the delaminated decals, and removing samples of the adhesive for analysis. In parallel, the adhesives manufacturer supplied our laboratory with a tin of each adhesive component.

Using Fourier Transform Infrared Spectroscopy (FT-IR) , we were able to determine the comparative composition of both adhesive batches and search the resulting spectra against reference spectra from our libraries. FT-IR works by exciting chemical bonds with infrared light, with the different chemical bonds while in this excited state, absorbing light energy at frequencies which are unique to the various bonds.

The Result: Our comparative FT-IR analysis showed that the adhesive samples supplied to our laboratory by the adhesive manufacturer, contained a sterically hindered phenolic antioxidant that protects the decals from thermo-oxidative degradation due to sunlight. The customer supplied suspect adhesive did not, obviously an adhesives manufacturing error. The adhesives manufacturer performed their own independent analysis of the adhesive and reached the same conclusions. Within two months, there was a financial settlement.