If you work with metals, whether as a former/forger/caster, a fabricator, a welder, in the construction industry or even just use metallic tools in other areas, the type of metal you use can have a significant impact of the job performance.

Materials Identification & Characterisation

If you work with metals, whether as a former/forger/caster, a fabricator, a welder, in the construction industry or even just use metallic tools in other areas, the type of metal you use can have a significant impact of the job performance.

The science of metallurgy can be compared to baking a cake. There are a lot of different ways to prepare it, depending on the requirements. There are standard recipes, but also some wiggle room. Just like some people adding a teaspoon of cinnamon for flavour, sometimes in metallurgy you need to add a teaspoon of manganese for strength in their metal.

One prime example of this is stainless steels. Steel in itself is a fascinating material with many alloying options, and stainless steels are a specialised subset, in which the element chromium is added, typically between 11% and 20% by weight. This is enough that the chromium interacts with the air to form a protective layer across the whole surface of the metal, known as a “passivating film”. This layer helps prevent many forms of corrosion, particularly rusting, making stainless steels a popular material for many tools and applications.

Other alloying elements can added for specific applications. Two of the most well-known grades of stainless steel are SAE 304 and 316. Type 304 is easily formed with good corrosion resistance, and is the more common type, widely used in machinery parts, food handling equipment, and in some construction applications. Type 316 has a similar composition, but with a key addition of molybdenum to improve corrosion resistance. This allows the use of type 316 in situations where type 304 would not be effective, such as chemical handling, marine environments, and human implants.

The investigation of the failure to function of adhesive bond and the technical examination of the material surfaces onto which the adhesive was applied.

Chemical analysis of adhesive to determine any batch-to-batch variation in raw materials. All investigative work uses our cutting-edge instruments, backed with a fully unbiased and scientifically valid expert opinion.

The Problem: If the incorrect grade of metal is used, significant problems can ensue. In one such case, a manufacturer of sailing components using formed 316 stainless steel parts produced a particular batch of equipment, which was found to fail at a higher rate.

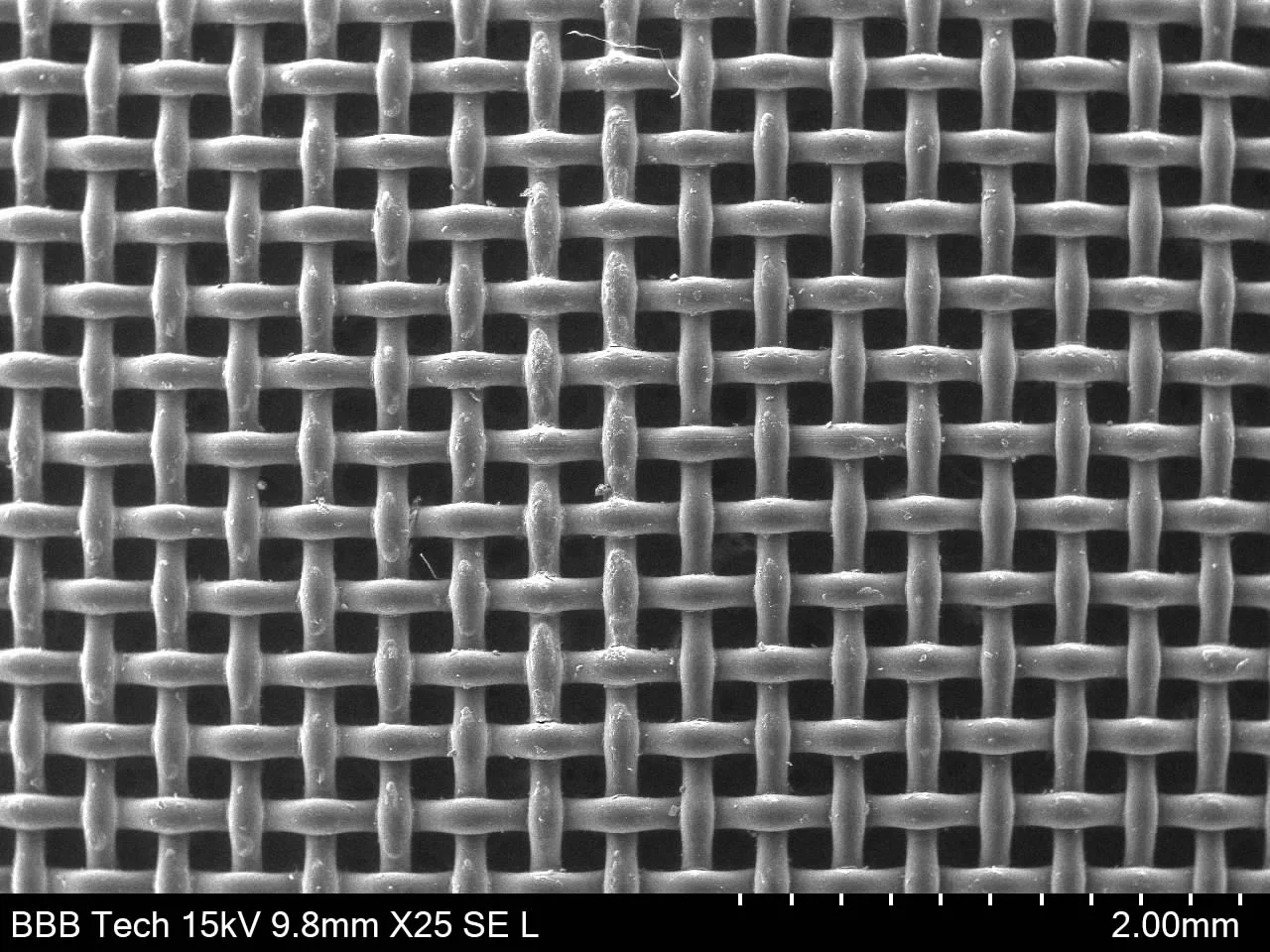

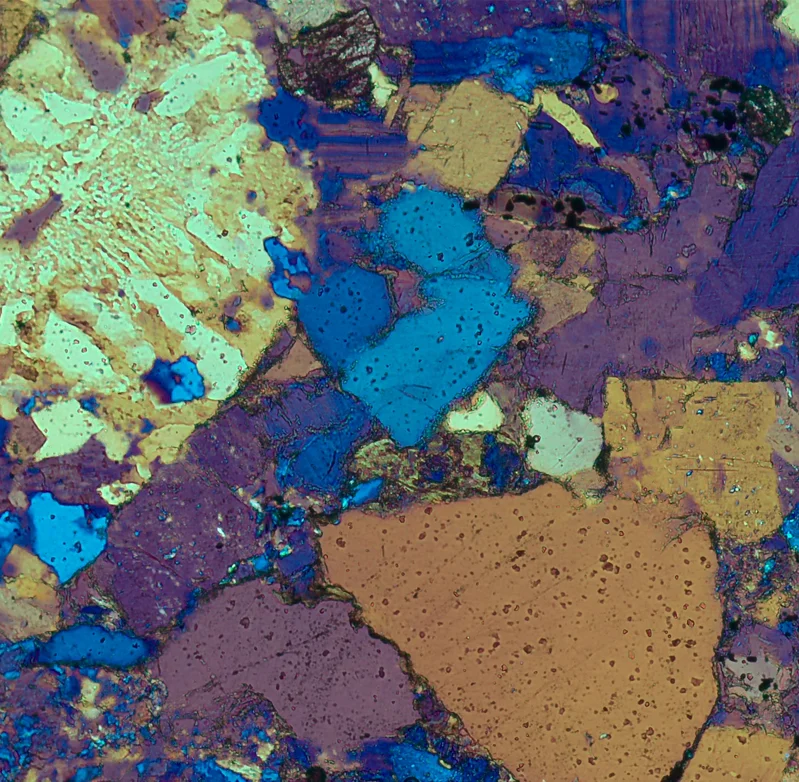

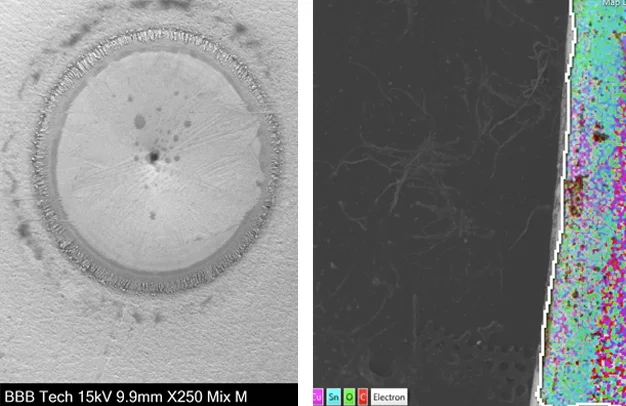

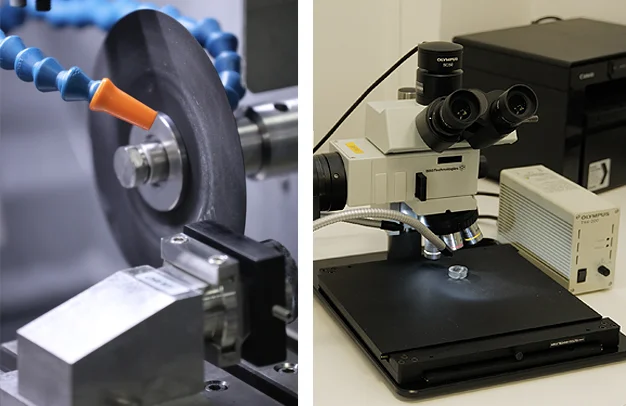

The Process: They sent a sample from this batch to the BBB Technologies Laboratory, where the component was sectioned, mounted in epoxy resin, ground and polished to a mirror finish, and analysed using Scanning Electron Microscopy and Energy Dispersive x-ray Spectroscopy.

The Result: This gave a breakdown of the elemental composition of the component, and it was found that type 304 stainless steel had been used, as no molybdenum was detected in the sample.

If stainless steel is too expensive too use, another way to protect a steel surface is by applying a coating of zinc, which forms its own protective coating. This process is more commonly known as “galvanising”, and is particularly popular for construction (Lightposts, guard rails, balconies, etc). The level and duration of protection provided is dependant on the environmental conditions, and the thickness of the layer of zinc coating applied. A typical coating 85 µm thick is expected to last at least 40 years, while a coating 140 µm is expected to last at least 67 years. If, however, no zinc coating is applied, the steel surface will rust with the next rainfall.

A lot of trouble can be saved by checking that your steel component has been correctly galvanised before using it. You can send a small representative sample to our BBB Technologies Laboratory, where we use special equipment based on magnetic principles to measure the exact thickness of your zinc coating.

Importers or distributors of both metal stock and components fabricated from metal. Manufacturers of items which partly of fully contain any type of metal.

Our business is solving problems, so talk to us now.

Contact us