Sealants have been given a simplified reputation in that somewhat like paint, it is assumed that anybody can put a cartridge of sealant into a gun and extrude it into a joint.

Failure Investigation

Sealants have been given a simplified reputation in that somewhat like paint, it is assumed that anybody can put a cartridge of sealant into a gun and extrude it into a joint.

This is not so as in paint application, the correct sealant, the correct surface to suit that sealant, and the correct surface preparation and application method is the difference between a good job and often years of costly litigation.

This is not so as in paint application, the correct sealant, the correct surface to suit that sealant, and the correct surface preparation and application method is the difference between a good job and often years of costly litigation.

The inspection and investigation of the in-service failure of all types of sealants in construction or general manufacturing applications.

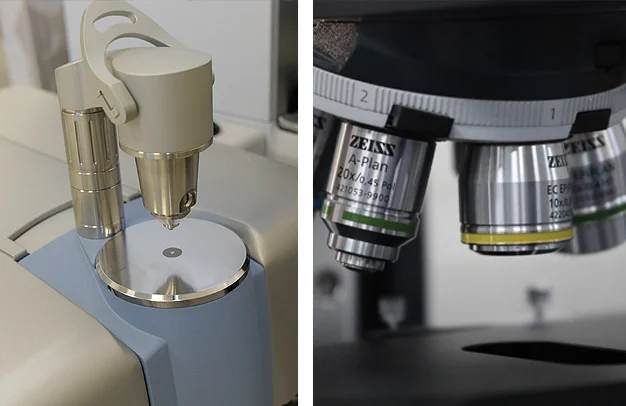

The technical examination of the both the joints and material forming the joint. Using dedicated analytical instrumentation, analyse the sealant and establish its raw material composition and establish if the recommended sealant was used.

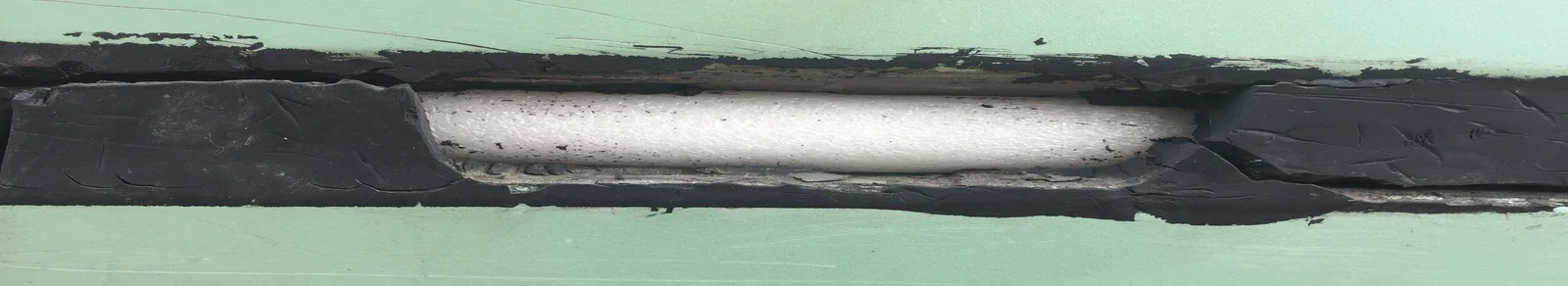

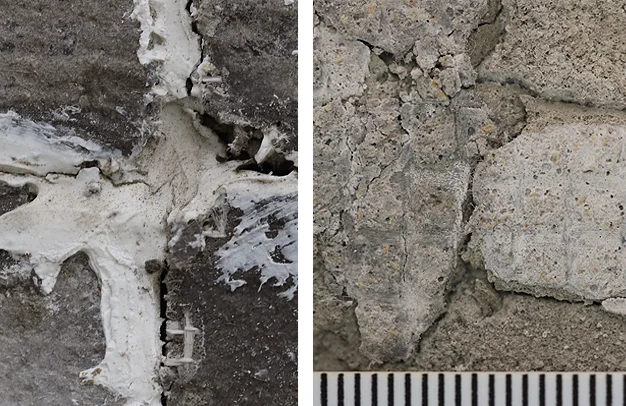

The Problem: A warehouse owner contacted us to say that in several locations, particularly at cross sections where four sheets of plastisol coated steel meet, the sealant is cracking. There was concern that water would penetrate and cause a corrosion issue to occur.

The Process: An engineer visited the site, inspected the areas of concern, measured both the Shore A Hardness of the sealant and the joint dimensions. Samples of the sealant were bagged, labelled and brought to the laboratory for analysis.

The Result: Using Fourier-transform infrared spectroscopy (FTIR) we obtained obtain an infrared spectrum of the sealant and it was shown to be a moisture cure polyurethane sealant, which was the correct sealant as specified by the Architect. The workmanship and joint design were the issue because typically, the depth of the joint must be equivalent to half of the joint width or a two to one width to depth ratio. In the attached photograph, the joint was filled with excess foam backing rod, which was not of continuous length. The sealant bead was approx. 2 mm thick, not sufficiently deep to allow for natural expansion and contraction of the joint.

Sealant Specifiers, Sales Agents, Architects, Building Contractors, Surveyors, Facilities Managers and Solicitors.

Our business is solving problems, so talk to us now.

Contact us