In the investigation of any contamination matter, it is vital in the first instance, to discover the chemical composition of the contaminate as knowing this from the outset, typically points to the source.

Materials Identification & Characterisation

In the investigation of any contamination matter, it is vital in the first instance, to discover the chemical composition of the contaminate as knowing this from the outset, typically points to the source.

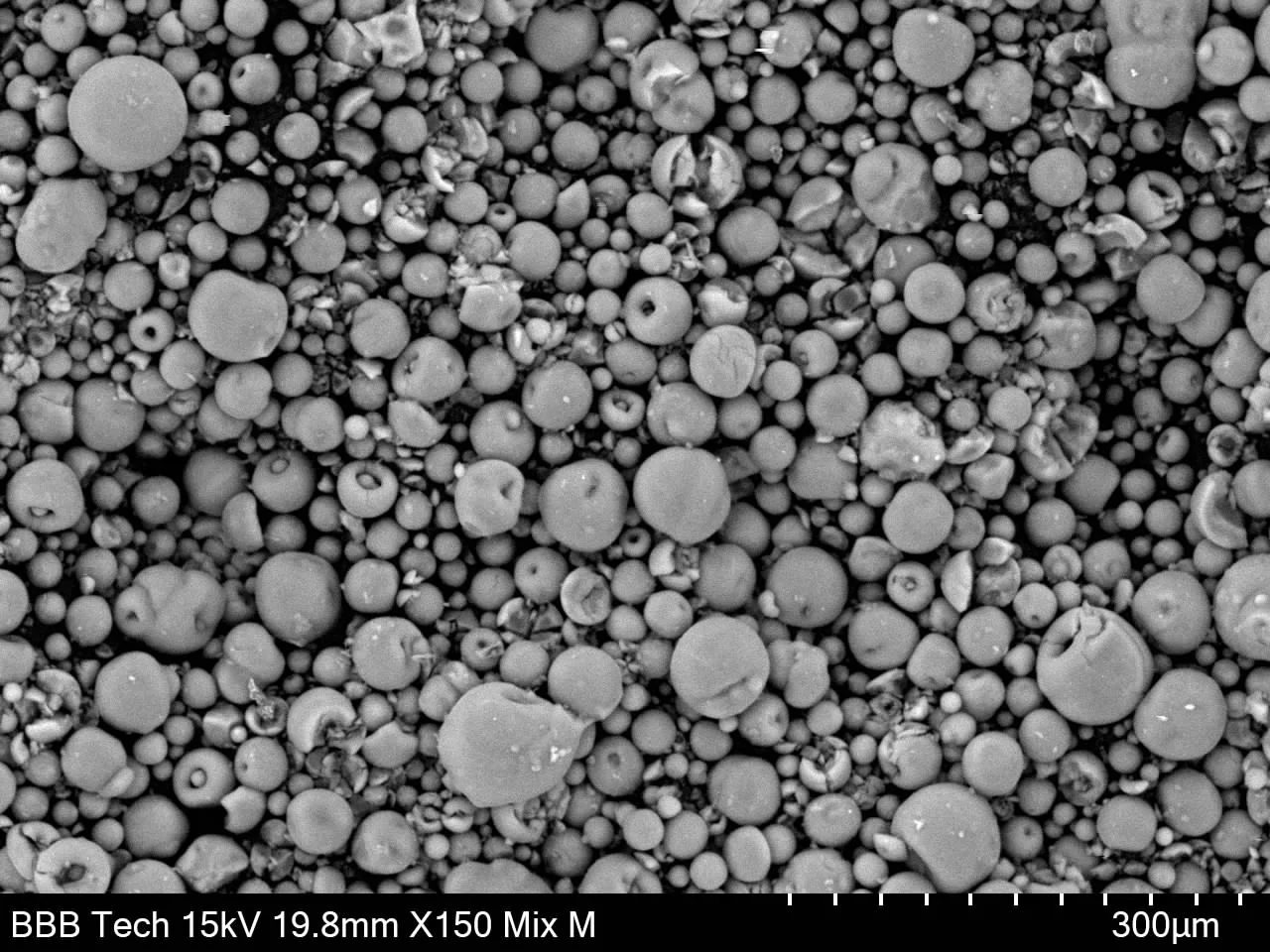

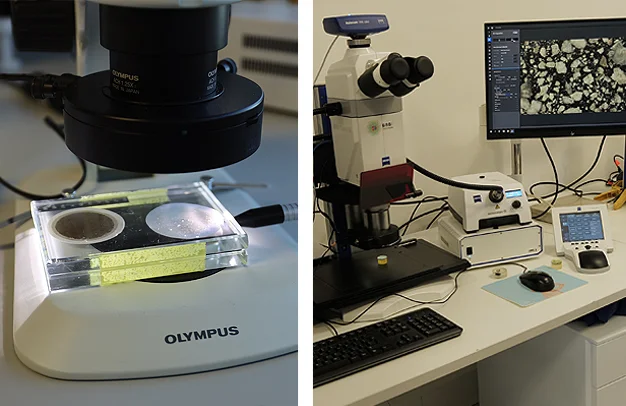

Amongst other techniques, we use both Fourier Transform Infrared Spectroscopy (FT-IR), with which we can establish the organic composition of the contaminate and using Scanning Electron microscopy (SEM) with Energy Dispersive Spectroscopy (EDS), we can establish the inorganic composition of the contaminate.

The range of contaminants which we have seen, is exhaustive, everything ranging from lubricating oils to particulate matter including plastics and occasionally, metal particles.

The identification of suspected contamination and the investigation of the composition of the contamination, and the likely source.

The identification of suspected contamination and the investigation of the composition of the contamination, and the likely source.

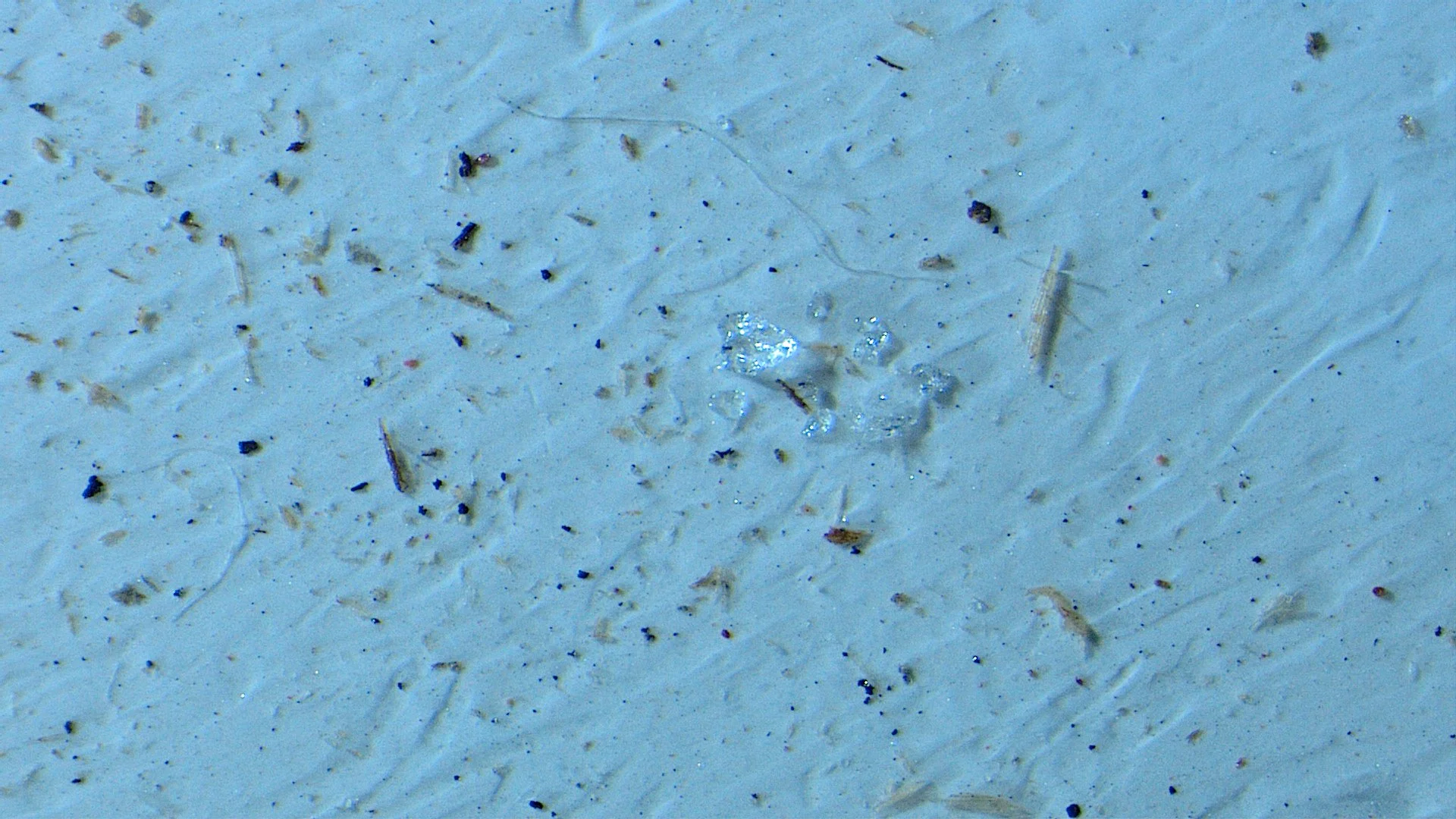

The Problem: During an internal quality audit, a food manufacturer discovered particulate contamination on a production line. We were informed that the contamination appeared to be ‘specs of plastic’.

The Process: Our laboratory was contacted, and we dispatched a chemist to site where a test specimen was obtained for analysis. The specimens were analysed using Fourier Transform Infrared Spectroscopy (FT-IR), and the resulting spectra was searched against reference spectra from our libraries.

The Result: Our FT-IR analysis identified the material as Nylon. Soon after the receipt of our Report, the Maintenance Manager of the food manufacturer sent us several roller bearings which were known to be Nylon and were located close to where the particulate contamination was originally seen. The spectra for the known Nylon were compared against the spectra for the Nylon contaminate and the spectra for Nylon contained in our spectra library, and all three spectra were identical.

In this case, in-depth analysis of the contaminant provided a fast resolution to what could have been, a very serious incident which could have required a product recall. There are many causes of contamination and when discovered could quickly become surrounded by hearsay and conflicting positions assumed, when litigation is a strong possibility.

Take the unknown out of product quality issues. Let our decades of expertise in the source location and identification of contamination, and the analysis of such contamination, work for you.

Companies manufacturing, distributing, or using any pure solid or powdered raw material or component where purity is quality critical.

Our business is solving problems, so talk to us now.

Contact us