How we found a solution for our client

The Problem: A manufacturer of abrasive discs was purchasing an abrasive powder. The Sales Specification for the abrasive powder gave a particle size range of between 100 µm and 200 µm. The abrasive disc manufacturer received 7 tons of abrasive, 10% of which would not pass through the manufacturers filter screens and therefore unsuitable for use in manufacturing.

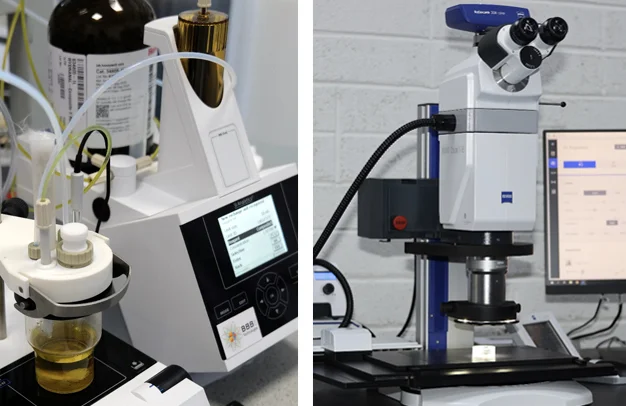

The Process: Our laboratory was contacted, and we dispatched a materials engineer to recover samples of the powder as delivered plus specimens of the material said to be out of the suppliers Specification. Back at our laboratory, the respective powders received a specimen number, after which, they were passed through a vibratory sieve which separated the powder into several fractions. Following this, the fractions were examined using a stereomicroscope.

The Result: Our analysis showed that abrasive powder as delivered, contained particles, 8% of which were below 100 µm and 13% of which were above 200 µm, therefore totally out of the suppliers Sales Specification. The matter did not go to litigation and the abrasive manufacturer was fully reimbursed. Having our analytical resources at his fingertips allowed the abrasive disc manufacturer to establish the root cause of his issue and allowed him to clearly establish where liability rested.