Forensic Engineering failure analysis, metallurgy and materials science forms a huge part of what we do, and clients from all over Ireland and abroad regularly contact our forensic materials laboratories for advice. Many of these cases involve personal injury and litigation.

Earlier this year, the laboratory was contacted by a Solicitor representing a client who stated that she had been ‘sitting on her office chair and whilst moving the chair out from under her desk, she fell to one side and landed on the ground". In so doing, she received an injury to her head, shoulder, and arm.

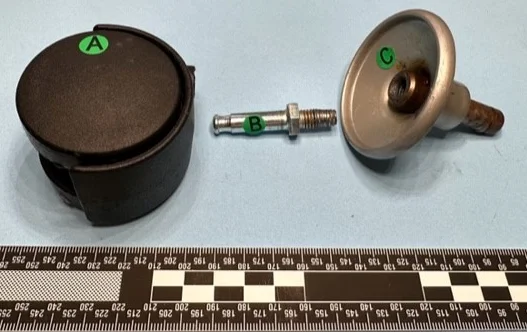

We had the chair collected from the employees office. The chair was a swivel 'egg-chair' which rested on a four spoke metal base. At the end of each spoke was a nylon castor. When delivered to the laboratory, one of the castor wheels was not attached to the spoke, rather it had been placed in a plastic bag and affixed to the chair post.

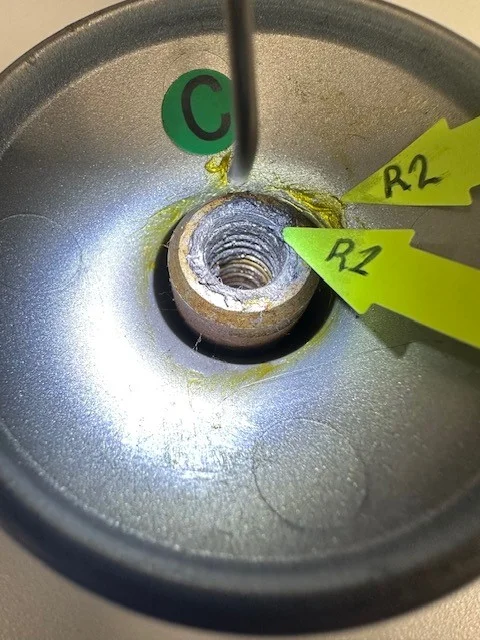

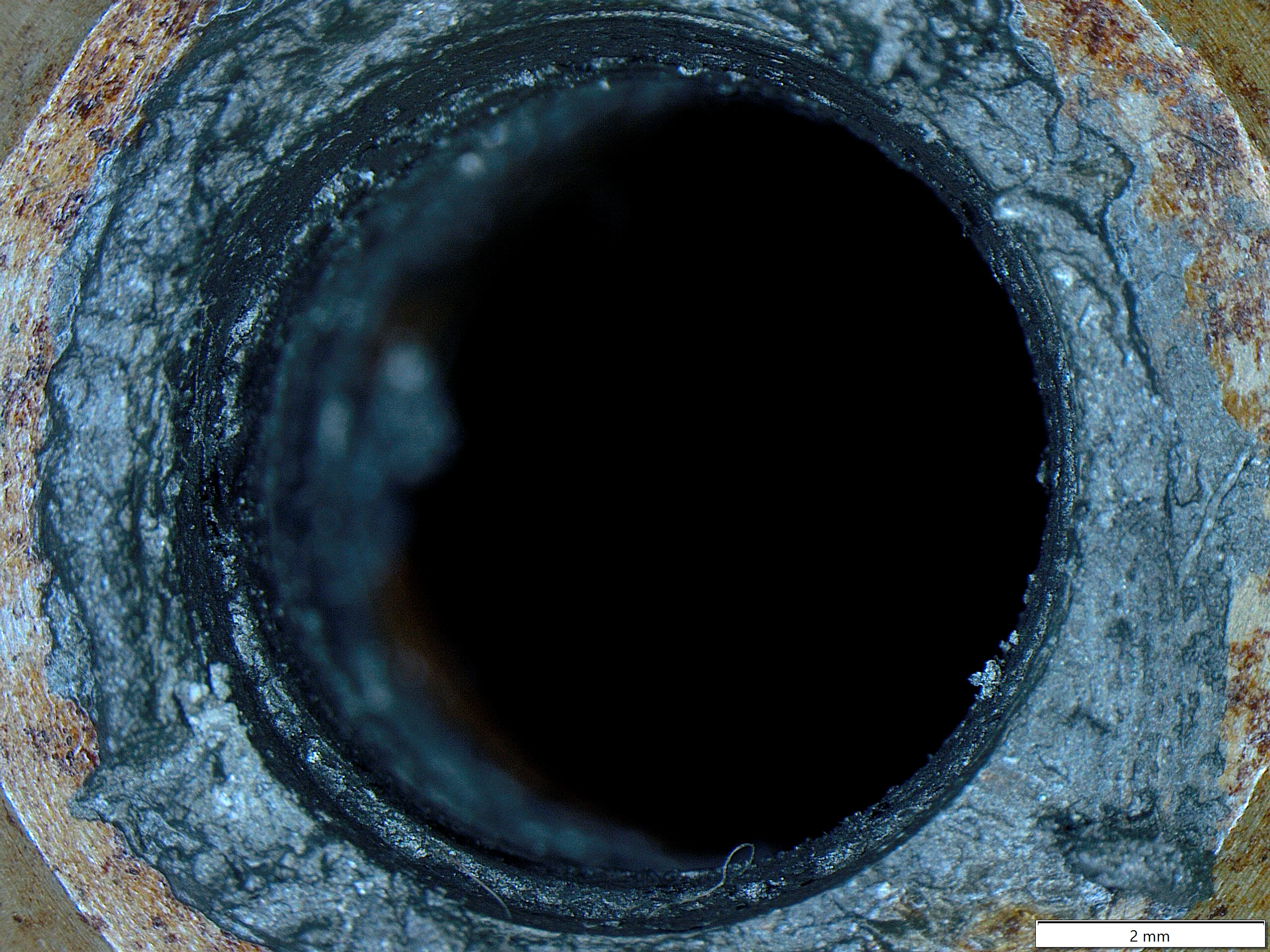

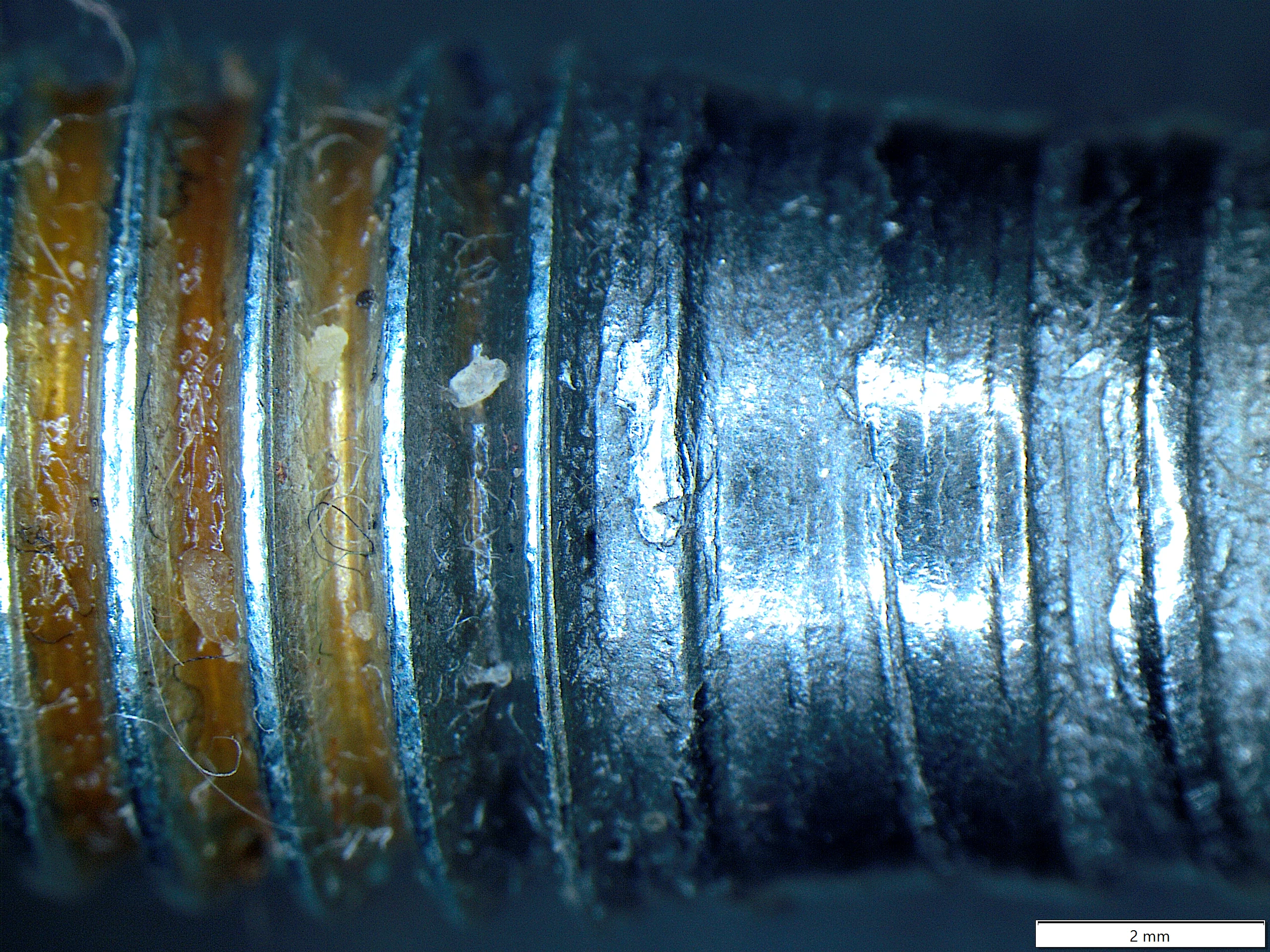

The castor assembly consisted of a plastic wheel (A), into which was a castor stem socket with a male thread at one end (B), with the male thread fitting into the female thread of wheel cover (C).