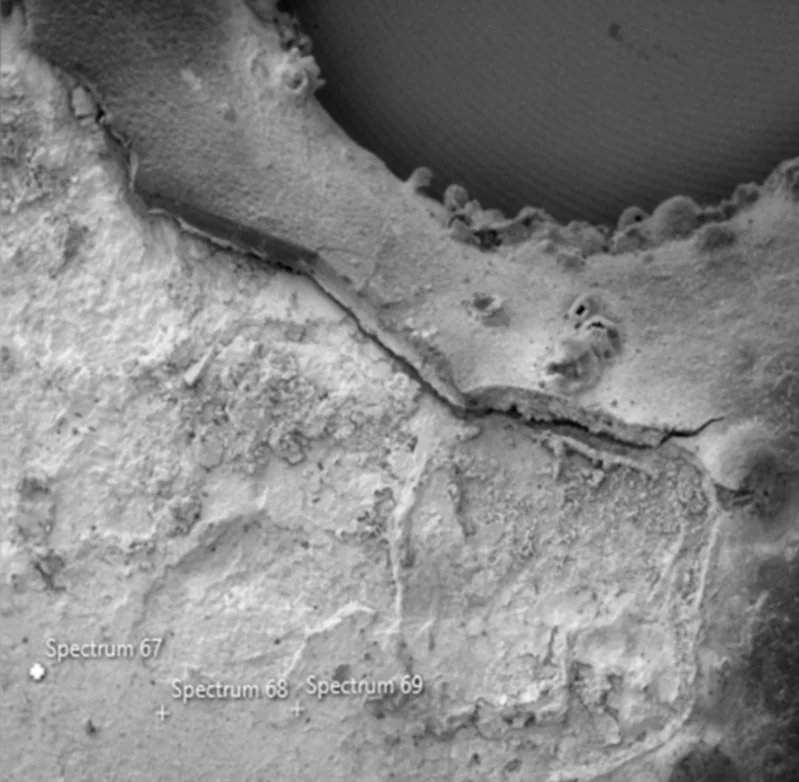

Paints offer both protection and, in some cases, an aesthetically pleasing surface. Paints work because they adhere well to the surface onto which they are applied, do not crack or fade and, slow down or prevent the ingress of chemicals. But what happens when the paint starts to fail and where does the liability rest?

Determining how and why a paint failed can be a complex matter as it involves the examination of various factors such as the right paint in terms of both the surface onto which the paint is being applied, the correct application and the correct paint for the conditions to which it will be exposed.

Recently, the laboratory was contacted by a firm of wholesale hardware distributors, who had received a delivery of 20,000 ‘T’ brackets which are commonly used to reinforce the ''T'' junction in post to beam and column to beam connections in timber structures.