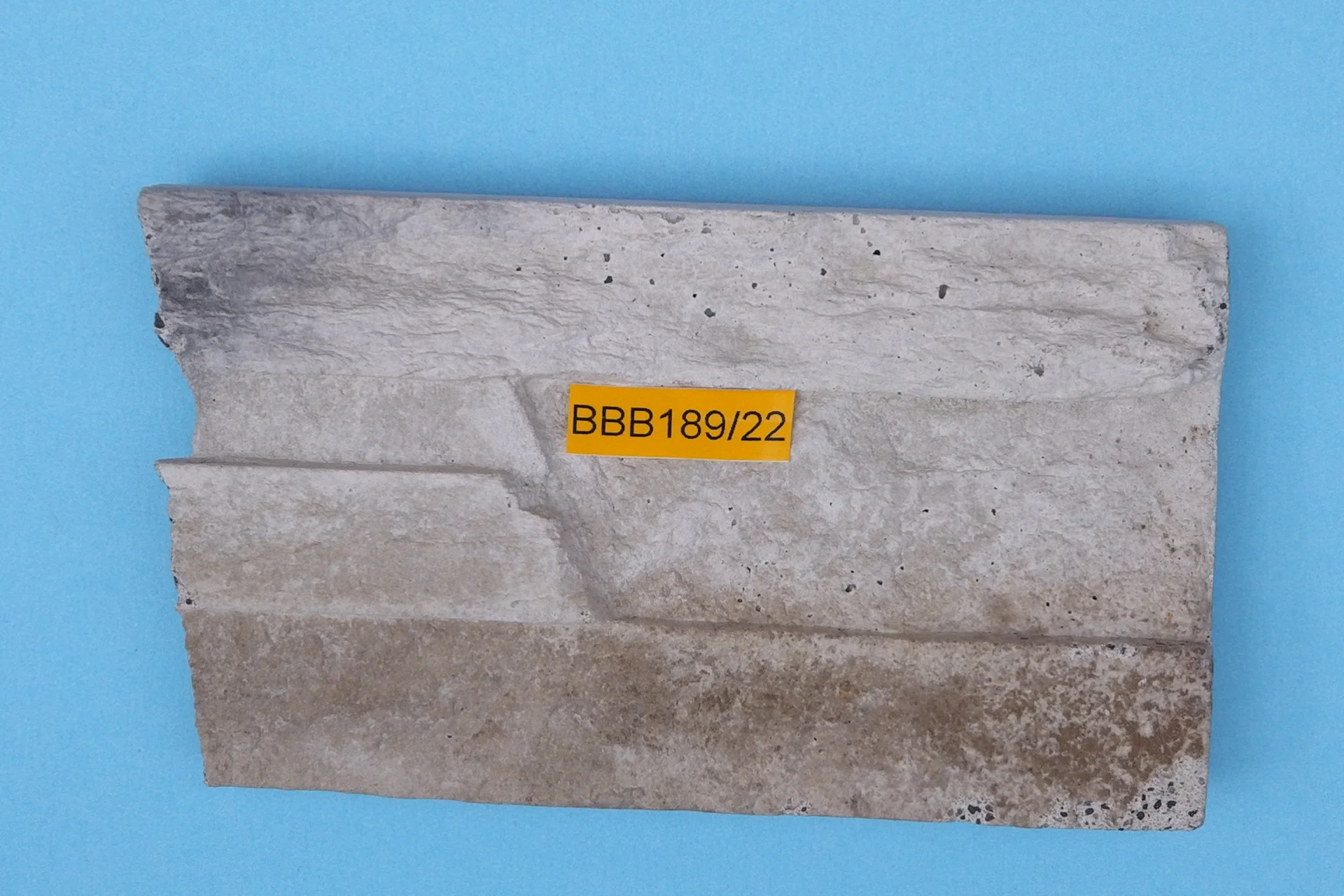

In conclusion we advised that the underlying cause of the issue was the failure to prime the receiving surface in advance of the brick slip being applied to the receiving surface. Then the adhesive coated brick slip was pressed onto the receiving surface, suction occurred wherein water contained within the cementitious adhesive, was sucked out and in so-doing, effecting the cure of the adhesive.

Irrespective of the situation, in all cases, the manufacturers advice must be adhered to and the system approach must never be deviated from.

In this case, the failure to prime the surface of the silicate board before the brick slips were applied, was the root cause of the failure. If the silicate board had been primed, with a primer other than what was specified by the brick-slip manufacturer, the contention could be made that the primer used was incompatible with the system. Simply put, in this case, the primer and adhesive specified for use with the specific type of brick slip, should have been used. Anything else could have pushed this matter into the long grass of claim, counterclaim and costly litigation.

We are experts in the provision of technical analysis on a wide range of materials so feel free to contact us.