Testing paint forms a large part of what our laboratory does. We very regularly receive retained quantities of paints which were used to coat anything and everything, from floors, to walls, to manufactured items.

Some clients, who use spray applied coatings as decorative and protective finishes for items such as street furniture, external building façade elements and such, often send us samples of painted steel or aluminium. With these test panels, we can carry out a range of both destructive and non-destructive tests to assess some of the properties of the dry paint film.

Another common request comes from manufacturing companies, who send us painted panels to ensure that their spray painting process or powder coating processes conform to their internal manufacturing processes. This is important as if the painting protocol is not being adhered to, time consuming and expensive claims may result. This is not only bad for the business as it can cause reputational damage, a precious thing.

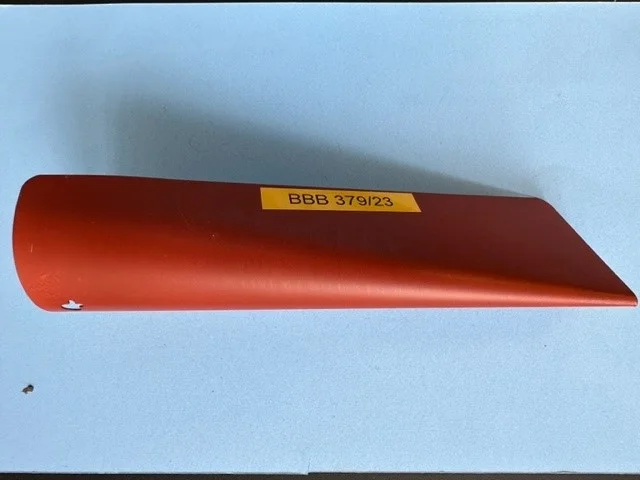

The flexibility (encompassing elasticity, elongation and adhesion), of a paint film is important mechanical property, most particularly where the paint is applied to materials such as steel, aluminium etc.

Why is this? Well in service, the paint film will have to have protective properties from such things as impact resistance and flexibility………the dry paint film will have to bend and flex without cracking

We use two different methods to determine paint film flexibility, these being a Cylindrical Mandrel and a Conical Mandrel and here, we will introduce the Conical Mandrel.