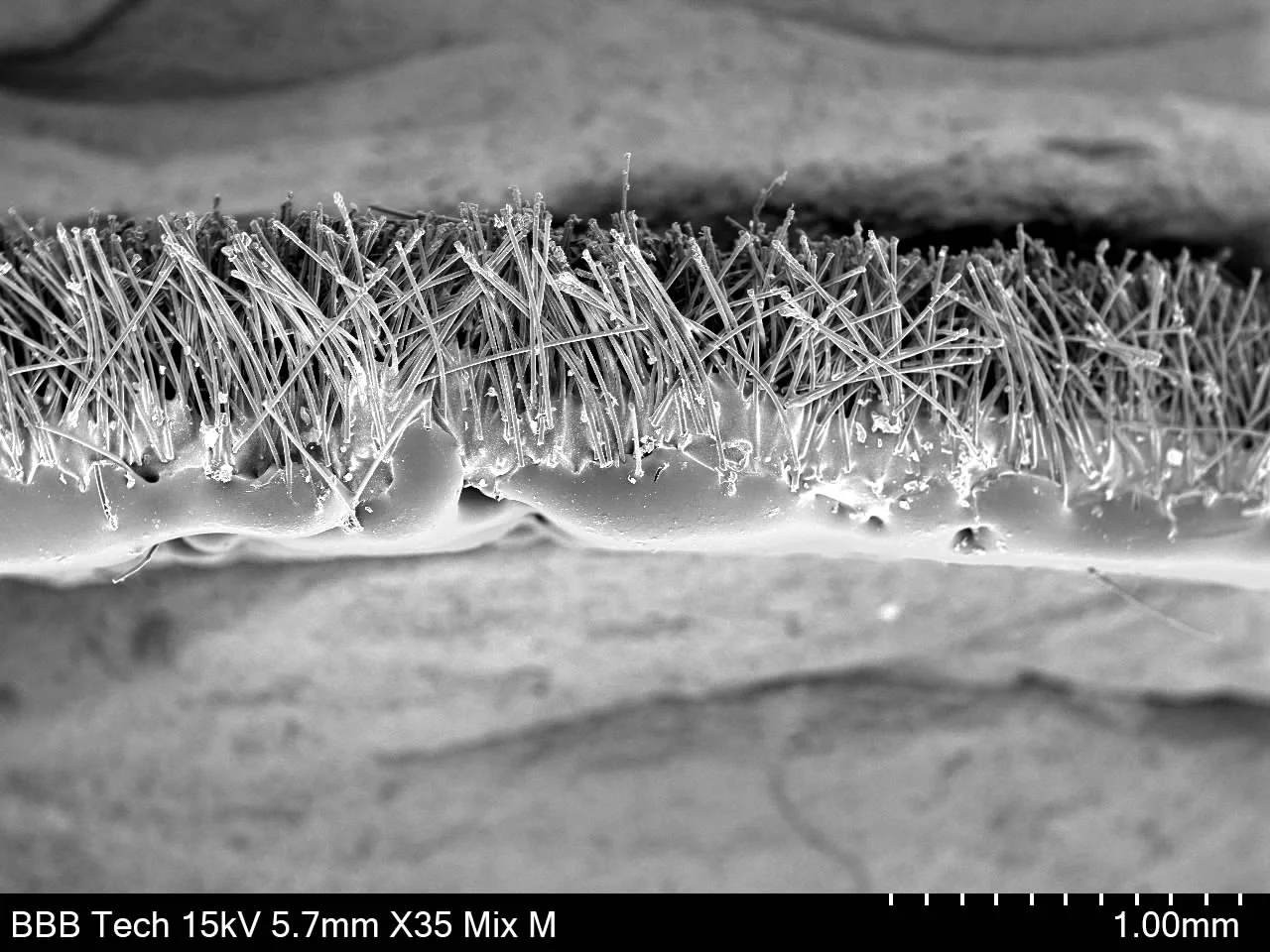

As a leading independent materials testing laboratory, we use a variety of instruments to elucidate the nature of materials. One technique is Scanning Electron Microscopy (SEM), which has emerged as a pivotal tool in materials science, enabling profound insights into the microcosm of various substances. Through the use of focused electron beams, SEM allows our investigators to captures intricate surface details, facilitating a deeper understanding of materials. Its applications span diverse areas, including failure investigation, elemental composition mapping, surface morphology analysis, particle analysis, corrosion studies, and nanotechnology exploration.

In materials analysis, SEM's prowess is evident in its ability to reveal surface textures, grain structures, and mechanical properties. It plays a crucial role in diagnosing failures by examining fracture surfaces and identifying defects. Coupled with energy-dispersive X-ray spectroscopy (EDS), SEM offers a comprehensive view of elemental distributions, assisting in material characterization and quality control.