Testing and analysing metals forms one of the functions which our laboratories undertake. This testing can take the form of failure analysis, corrosion investigation, chemical analysis and macro/micro inspection. One very longstanding technical service which we have provided to metal component importers and sellers, is that of quality verification.

There are hundreds of metal part and component importers all over Ireland, importing components from Europe, Asia and the Americas. Many of these components are mechanical fixings and fasteners and for this segment, we have been a longstanding provider of quality verification services. Quality verification is important as occasionally, through no fault of the importer, fixings and fasteners may be physically or chemically different from that purchased. Our quality verification is detailed, and involves a suite of testing including eight measurement geometric measurements, metallographic analysis using scanning electron microscopy, elemental analysis using x-ray fluorescence, x-ray spectroscopy and Hardness Testing (Rockwell C).

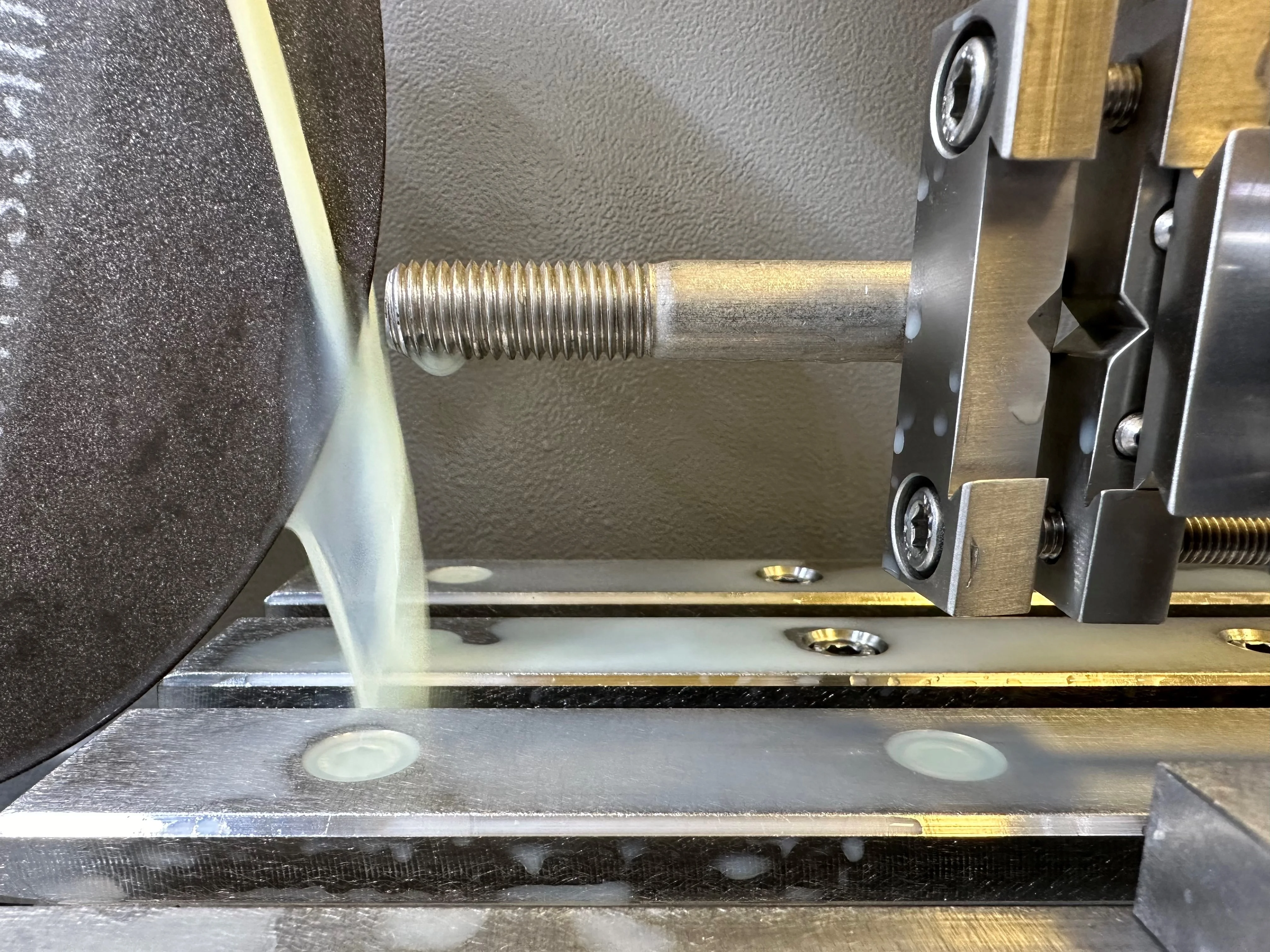

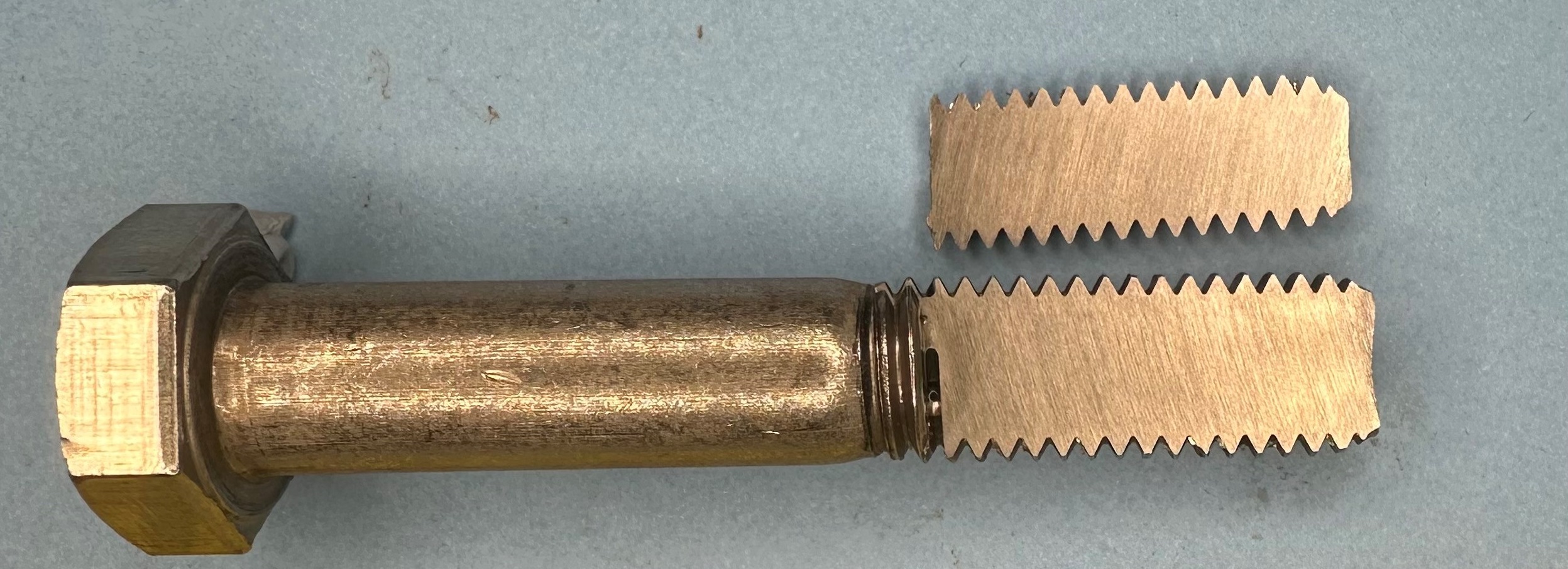

Earlier this year we were contacted by a longstanding importer of fasteners who had advised us that a corrosion issue had arisen with a consignment of ‘half thread austenitic stainless steel bolts’.