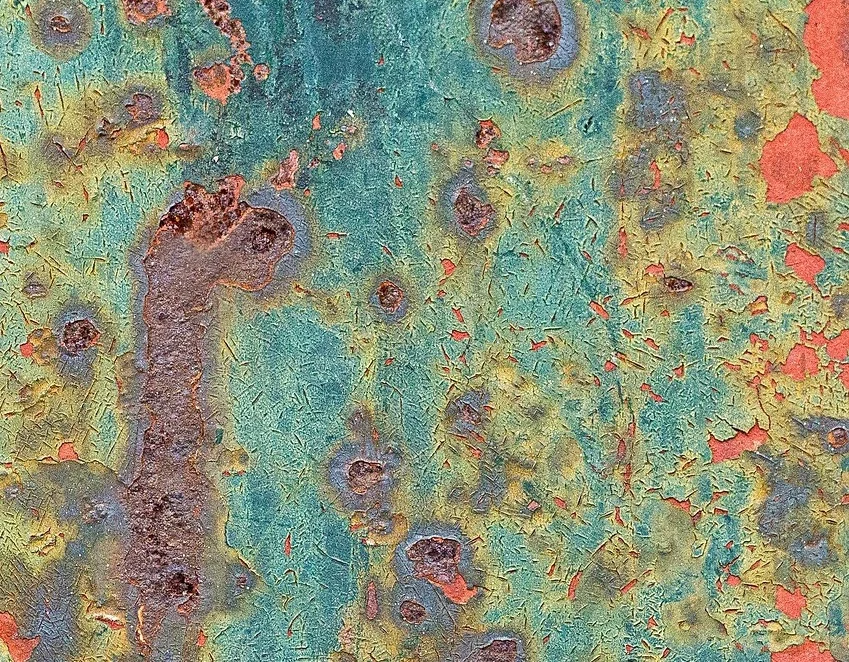

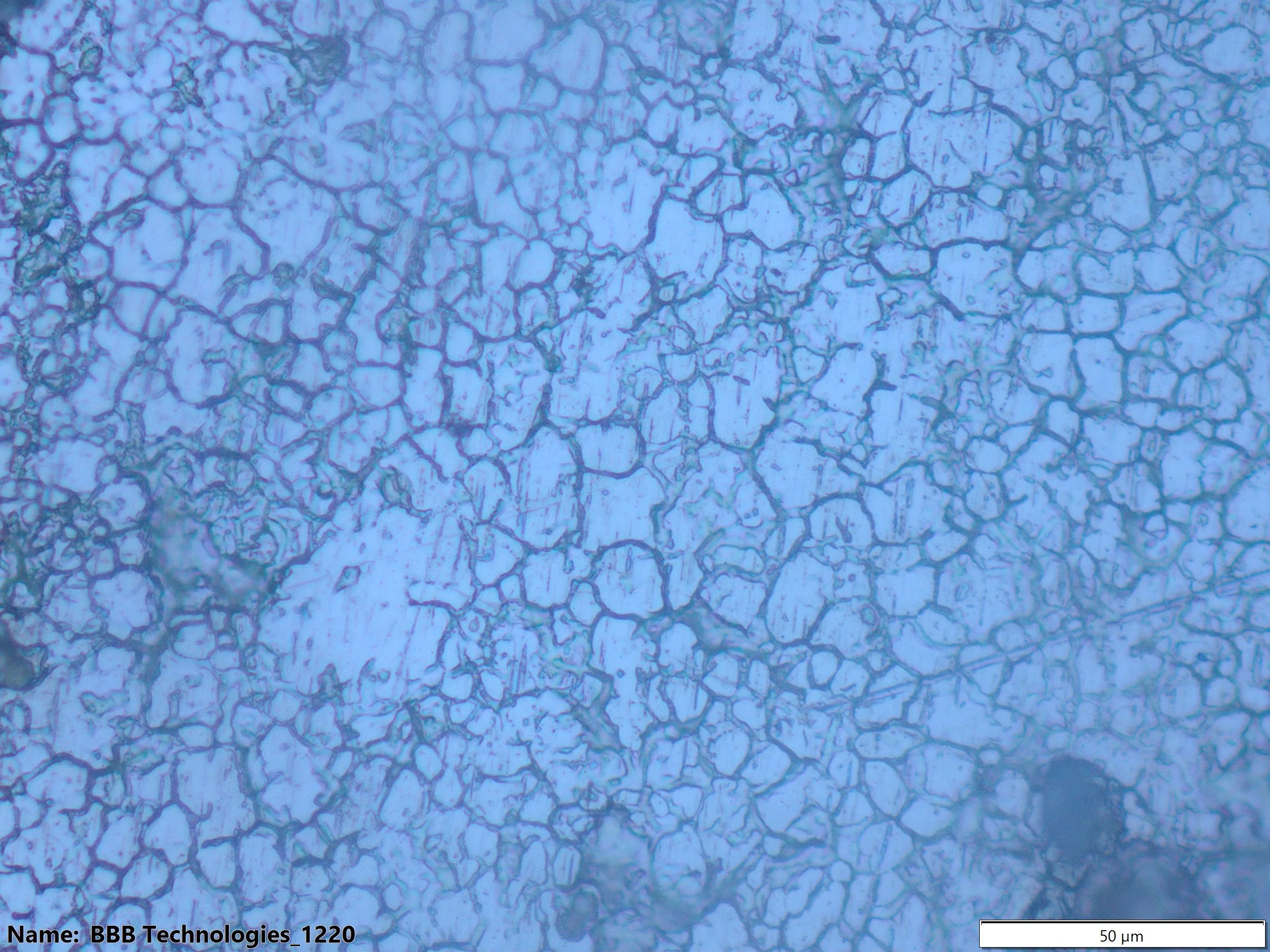

Materials testing and analysis forms the core of our business. One recurring investigation involves the cause and effect of corrosion of metals.

The effects of corrosion can be both beautiful and costly and here at BBB Technologies forensic materials laboratories, we routinely investigate the cause and mechanism of corrosion, and if a liability exists, establish where it lies. We also commonly advise on corrosion protection, particularly in structural steel applications.

If it is not prepared for and managed correctly, corrosion process can begin and propagate rapidly, potentially causing significant damage.