Our laboratories are very regularly asked to investigate insurance claims where paint is failing. These failures can encompass colour fading, loss or adhesion, cracking or peeling. One commonly seen paint system are PVC plastisol paints. PVC plastisol coatings are found in a variety of applications including significant use in the manufacture of PIR insulation panels and every year, we are asked to investigate why such coatings fail in service and what remediation steps can be carried out.

In our experience, these coatings tend to be in service for ten plus years before an issue arises, and in general, may be due to manufacturing errors, such as poor surface preparation during manufacture, are rare as most typically, the application of the plastisol coating is carried out on a dedicated production line.

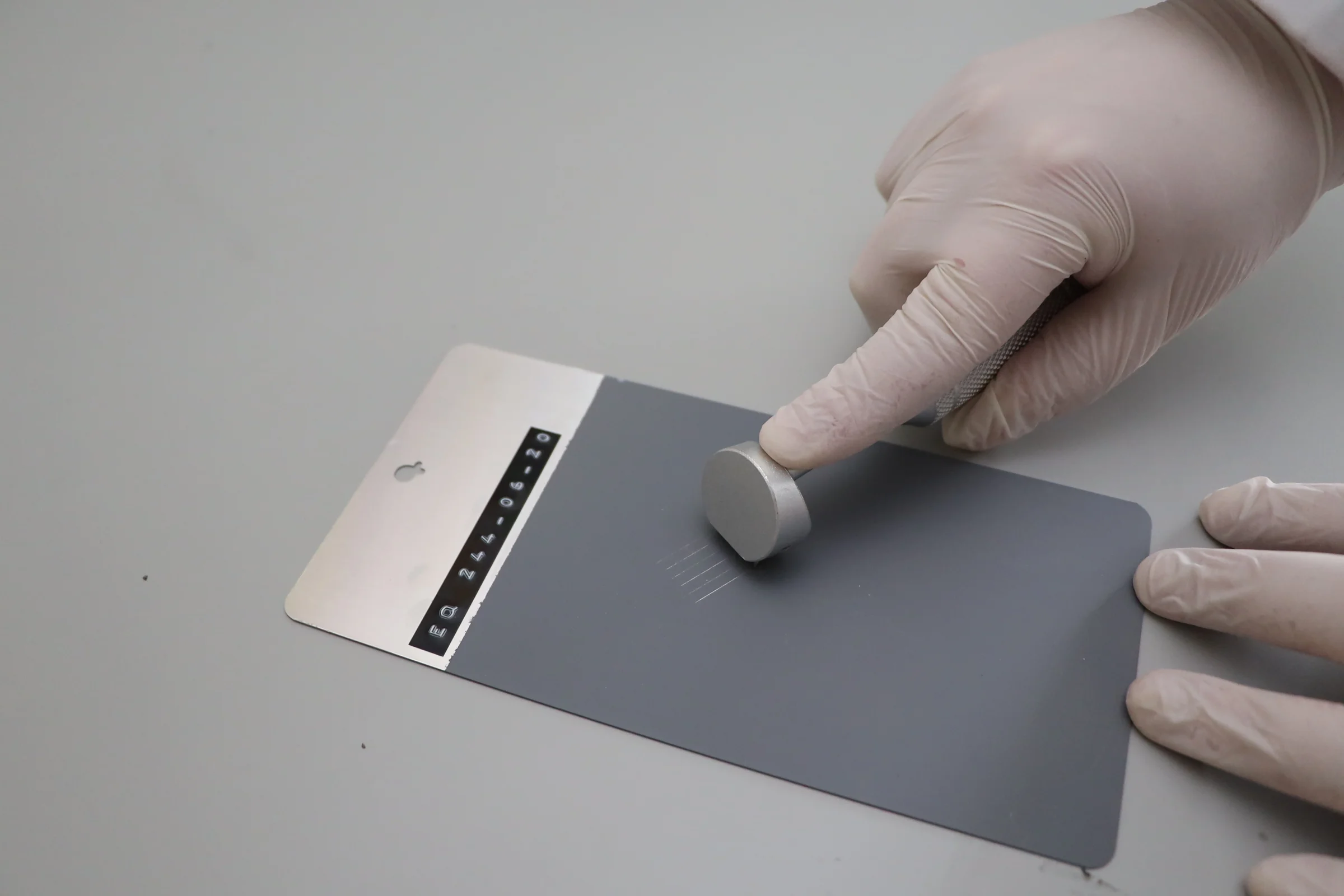

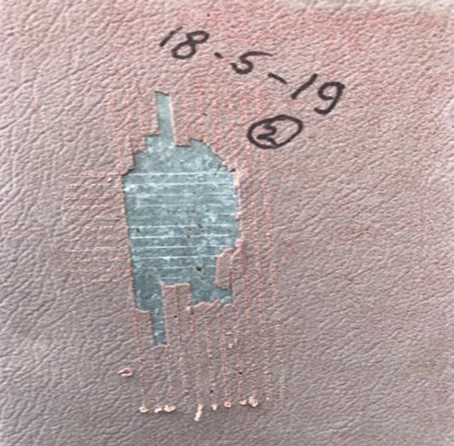

The failure can be evidenced by a few specific features, most typical is a change in colour, most evident where the coating is exposed to sunlight. Embrittlement of the coating is always evident and our laboratory always carries out a Cross Hatch Test in accordance with ASTM D3359 : 2017.