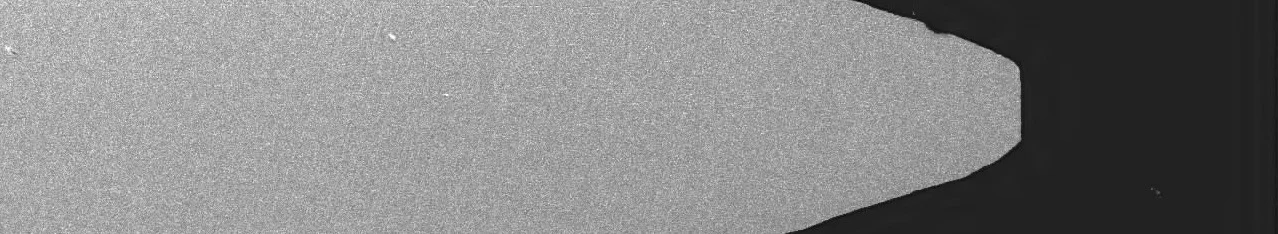

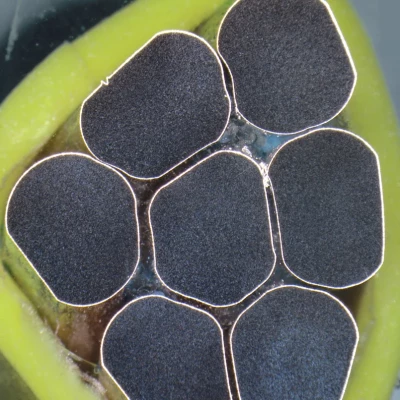

Automated cutting equipment and metallographic techniques offer invaluable tools for examining the purity and internal damage of copper wires. Firstly, automated cutting equipment ensures precise and consistent cutting of the wire samples, minimizing human error and providing standardized test specimens. This equipment allows for the creation of cross-sections of the wire, enabling a comprehensive examination of the internal structure.

Once the wire samples are prepared, metallographic techniques can be employed to study the copper's purity and internal characteristics. Metallography involves the preparation, analysis, and interpretation of the microstructure of metals and alloys. By using optical microscopes or electron microscopy, metallurgists can observe the grain structure, impurity inclusions, and any defects or damage within the copper wire. This enables a thorough assessment of its quality, such as identifying impurities or voids that may affect its conductivity or mechanical strength.