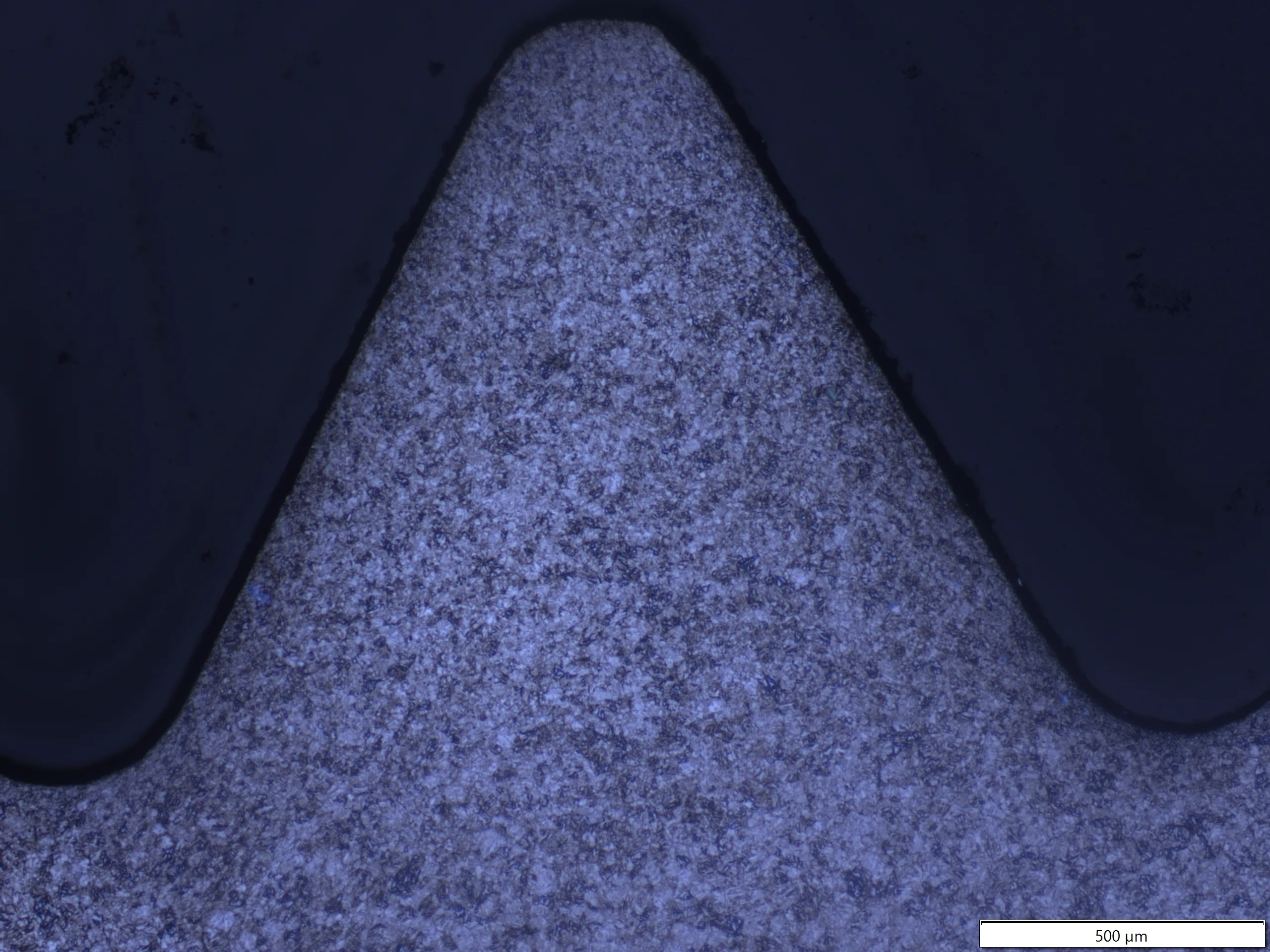

In the realm of material analysis, where precision and accuracy are paramount, the technique of etching is an established powerful tool. Specifically, when it comes to understanding the properties and characteristics of mild steel, etching plays a pivotal role.

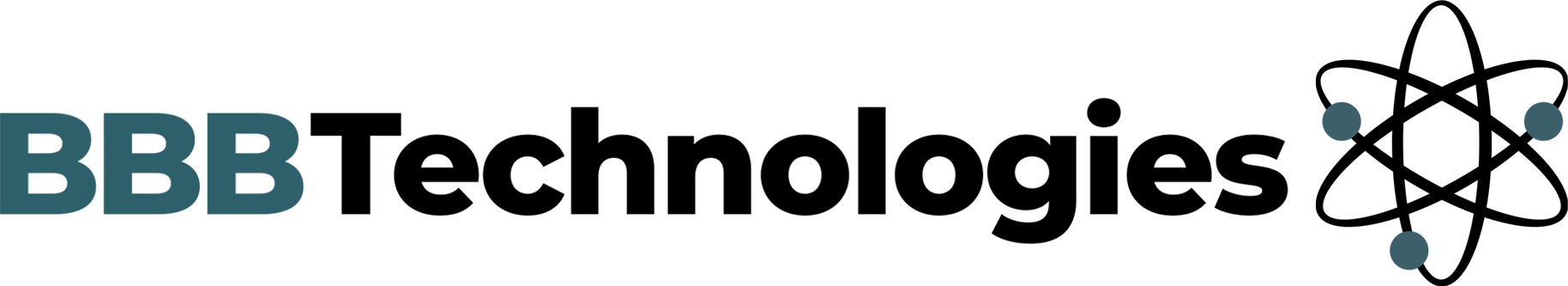

Through controlled chemical reactions, etching unveils hidden patterns and structures within the steel, offering invaluable insights to engineers, metallurgists, and researchers alike. To begin, a polished cross section of the component is prepared, such as the threads on a steel bolt. You can read more about this process here. Because the steel surface has been polished to a mirror-like finish, examining the surface using light microscopy gives a washed-out appearance, and its hard to make out details. This is why we need to etch the sample.