Supply line disruptions have impacted many aspects of our industrial world, with knock-on effects in all corners of our life.

Quality Control

Supply line disruptions have impacted many aspects of our industrial world, with knock-on effects in all corners of our life.

Scarcity of materials and rising costs has driven many manufacturers to acquire components and raw materials from non-OEM sources.

Depending on the end-use of these un-authenticated materials, there may be disastrous consequences if the material does not meet specification. Without OEM guarantees, this could be calamitous for the company.

Most components or raw materials have some form of specification, technical data sheet, or certificate of analysis which provides crucial information to authenticate it. If you send a sample to BBB Technologies, we can test your sample and compare it to the specified values. To be absolutely sure of the authenticity, if you can send a guaranteed OEM sample, we can make a direct comparison between the OEM and suspect samples. Let us show you how our analysis can give you confidence in the authenticity of your products.

Take the unknown out of raw materials and components. Our decades of expertise in the chemistry and technology of materials, backed up by and evidenced using our suite of analytical equipment, will provide a proof positive understanding of your materials matters.

Using cutting edge physical and chemical analysis, we can examine and test the defining properties of the material, such as the material used, the purity of the material (e.g. gold, silver), or other specifications given in relevant technical documents.

If a guaranteed authentic item can be provided, we can perform a direct comparison between authentic and suspect items or materials

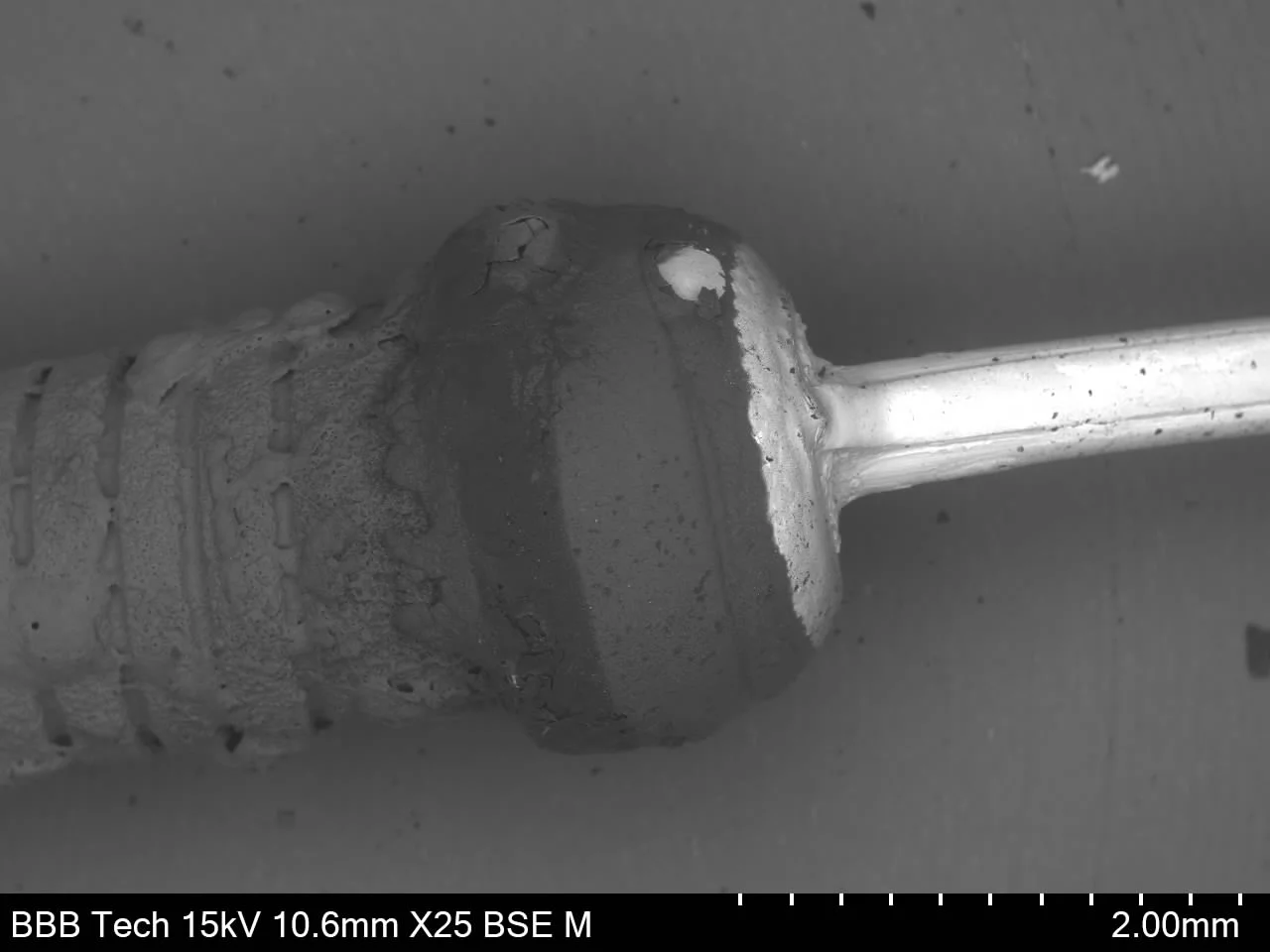

The Problem: A manufacturer of electrical goods, who purchases components and assembles them into value-added products, was facing long lead-times in acquiring some components from OEM sources. Equivalent components were available from other sources, but without OEM guarantees – the so called “Grey Market”. Samples of these “Grey” components were acquired, and send to the BBB Technologies Lab, along with samples from a guaranteed OEM source, and all relevant technical literature.

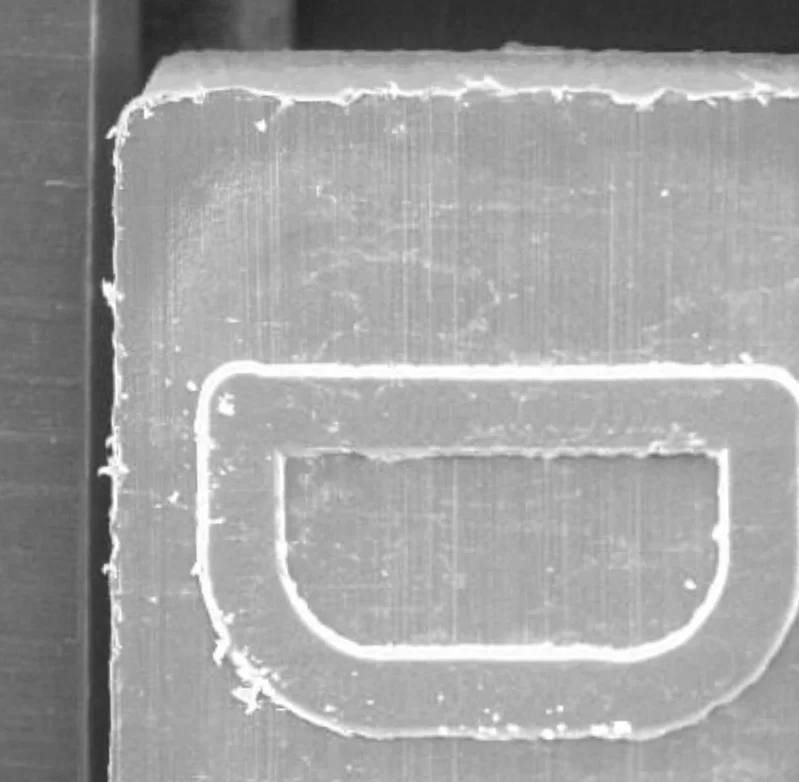

The Process: To evaluate the authenticity of the grey component, it was evaluated in terms of physical properties, material composition, and factory marks. The supplied technical literature and OEM sample provided a reference for the physical dimensions and mechanical properties of the component. Chemical analysis, using our Lumos II FTIR Spectrophotometer, identified that the grey component was made of material identical to that of the OEM component, and matched the technical literature. Finally, the factory marks were examined using a range of optical and scanning electron microscopy, comparing the appearance on the grey component with the OEM component.

The Result: With satisfactory results from all three aspects of analysis, our client was satisfied with the authenticity of the grey components and proceeded with their purchase from the non-OEM source, bypassing the excessively long lead-time.

Manufacturing companies who must source components from a “grey” market or other areas where authenticity cannot be guaranteed, jewellers or other artisans using precious materials, consumers purchasing second-hand or “discount” items of dubious origin.

Our business is solving problems, so talk to us now.

Contact us